Base

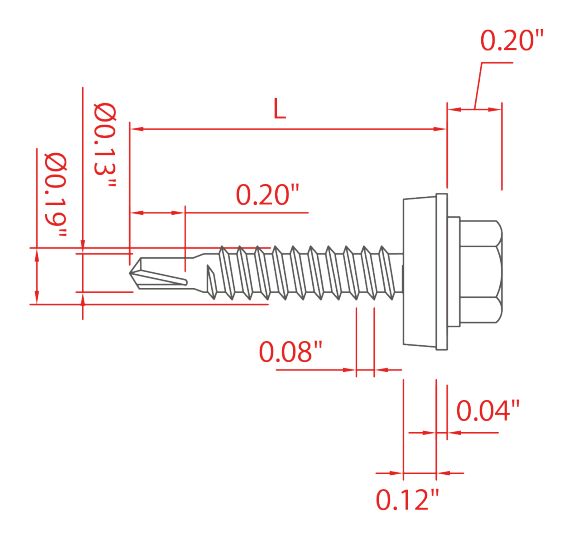

Cross section

Order information

| Product | Size | Packaging | Article code |

|---|---|---|---|

| Self-drill metal tile sheet screw #10 x 3/4" x L - DP1 | 3/4" | 250 pcs/box | 2004014802014 |

| Self-drill metal tile sheet screw #10 x 1" x L - DP1 | 1" | 250 pcs/box | 2004014802814 |

| Self-drill metal tile sheet screw #10 x 1 3/8" x L - DP1 | 1 3/8" | 250 pcs/box | 2004014803514 |

| Self-drill metal tile sheet screw #10 x 1 7/8" x L - DP1 | 1 7/8" | 150 pcs/box | 2004014805014 |

| Self-drill metal tile sheet screw #10 x 2 1/4" x L - DP1 | 2 1/4" | 150 pcs/box | 2004014806014 |

| Self-drill metal tile sheet screw #10 x 3 1/8" x L - DP1 | 3 1/8" | 100 pcs/box | 2004014808014 |

Mechanical properties

17/32''

5/8''

3/4''

| Materials | ||

|---|---|---|

| Screw | Galvanized steel |

|

| Bond washer | Galvanized steel | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

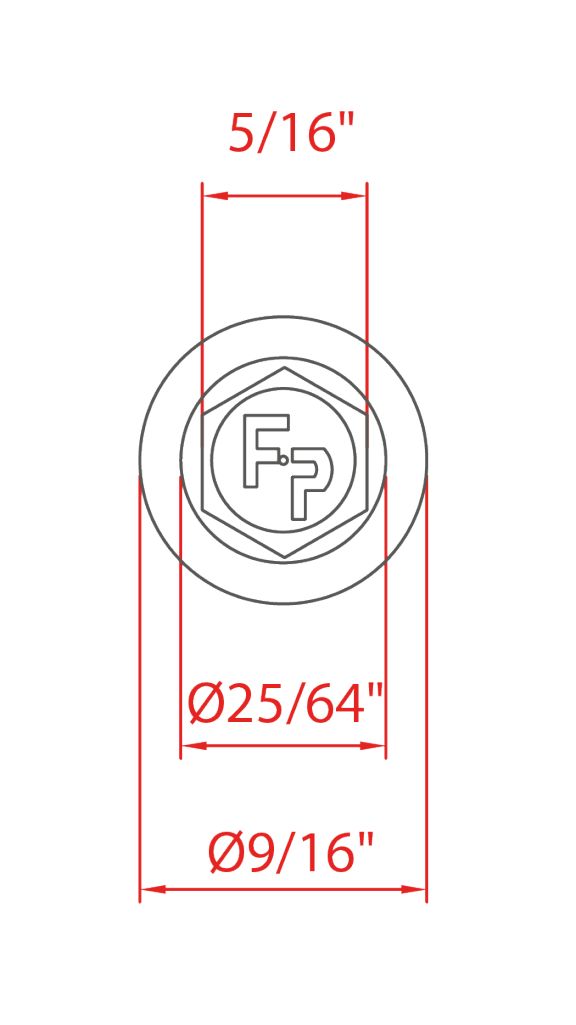

Washer diameter

17/32 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | ||||

|

VR,k [kN] | 28 Ga | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | |

| 26 Ga | 175 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | |||

| 25 Ga | 175 | 233 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | |||

| 23 Ga | 175 | 233 | 272 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | |||

| 22 Ga | 175 | 233 | 272 | 332 | 427 | 427 | 427 | 427 | 427 | 427 | 427 | |||

| 21 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 20 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 19 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 18 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

|

NR,k [kN] | 28 Ga | 76 | 116 | 132 | 159 | 197 | 283 | 283 | 283 | 283 | 283 | 283 | |

| 26 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 440 | 440 | 440 | |||

| 25 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 465 | 465 | 465 | |||

| 23 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 503 | 503 | |||

| 22 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 564 | 564 | |||

| 21 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 564 | 564 | |||

| 20 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 564 | 564 | |||

| 19 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 564 | 564 | |||

| 18 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 564 | 564 | |||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Galvanized steel |

|

| Bond washer | Galvanized steel | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

Washer diameter

5/8 "

| tN1 [inch] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | ||||

|

VR,k [kN] | 28 Ga | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | |

| 26 Ga | 175 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | |||

| 25 Ga | 175 | 233 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | |||

| 23 Ga | 175 | 233 | 272 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | |||

| 22 Ga | 175 | 233 | 272 | 332 | 427 | 427 | 427 | 427 | 427 | 427 | 427 | |||

| 21 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 20 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 19 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 18 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

|

NR,k [kN] | 28 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 290 | 290 | 290 | 290 | 290 | |

| 26 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 445 | 445 | 445 | |||

| 25 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 496 | 496 | |||

| 23 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 577 | 577 | |||

| 22 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 701 | |||

| 21 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 701 | |||

| 20 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 701 | |||

| 19 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 701 | |||

| 18 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 701 | |||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Galvanized steel |

|

| Bond washer | Galvanized steel | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

Washer diameter

3/4 "

| tN1 [inch] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | ||||

|

VR,k [kN] | 28 Ga | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | |

| 26 Ga | 175 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | 233 | |||

| 25 Ga | 175 | 233 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | 272 | |||

| 23 Ga | 175 | 233 | 272 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | |||

| 22 Ga | 175 | 233 | 272 | 332 | 427 | 427 | 427 | 427 | 427 | 427 | 427 | |||

| 21 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 20 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 19 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

| 18 Ga | 175 | 233 | 272 | 332 | 427 | 685 | 685 | 685 | 685 | 685 | 685 | |||

|

NR,k [kN] | 28 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 319 | 319 | 319 | 319 | 319 | |

| 26 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 553 | 553 | |||

| 25 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 584 | 584 | |||

| 23 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 631 | |||

| 22 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 705 | |||

| 21 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 705 | |||

| 20 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 705 | |||

| 19 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 705 | |||

| 18 Ga | 76 | 116 | 132 | 159 | 197 | 290 | 350 | 418 | 478 | 606 | 705 | |||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Galvanized steel |

|

| Bond washer | Galvanized steel | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

"