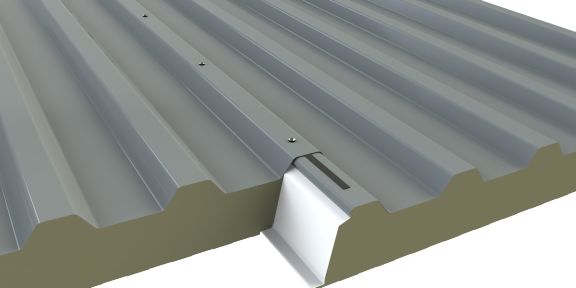

Base

Cross section

Order information

| Product | Size (L) | Packaging | Article code |

|---|---|---|---|

| Self-drill metal tile sheet screw #10 x 1" - DP1 | 1" | 250 pcs/box | 2001014802814 |

| Self-drill metal tile sheet screw #10 x 1 3/8" - DP1 | 1 3/8" | 250 pcs/box | 2001014803514 |

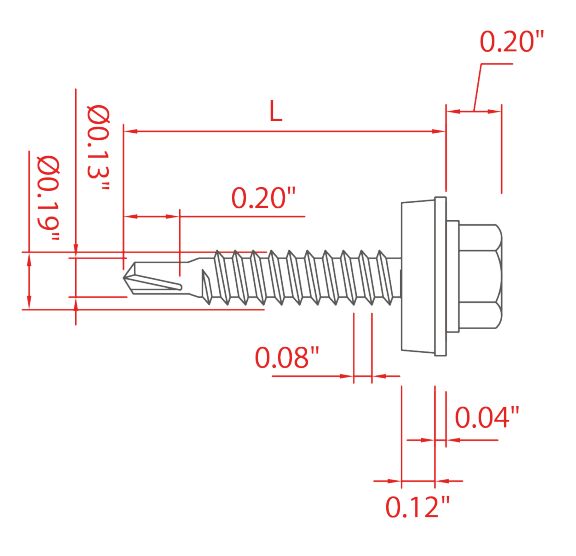

Mechanical properties

17/32''

5/8''

3/4''

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | Steel Quality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | Steel Quality S235 – according to EN 10025-2 en S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

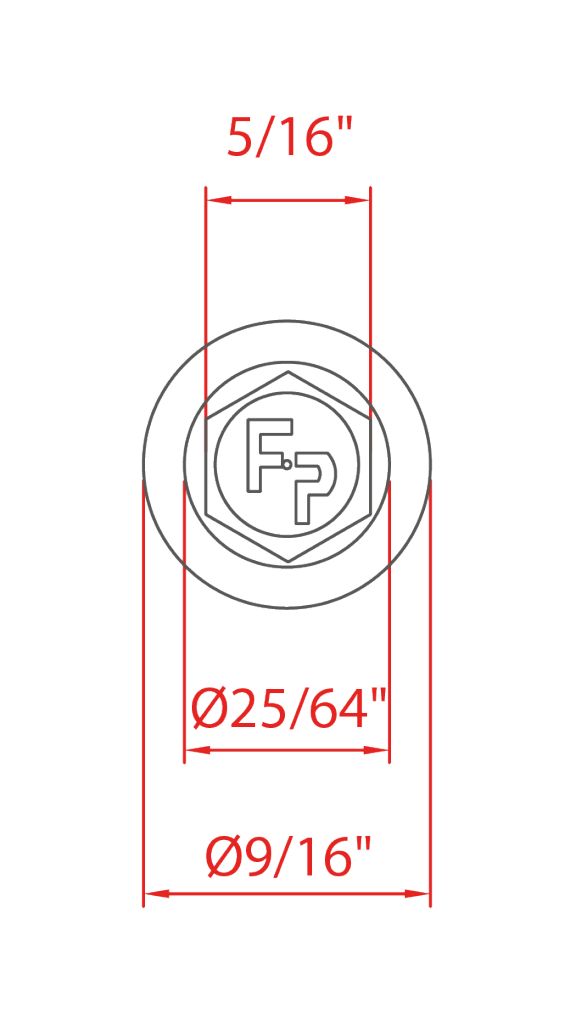

Washer diameter

17/32 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | |||||

|

VR,k [kN] | 28 Ga | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | ||

| 26 Ga | 143 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | ||||

| 25 Ga | 143 | 204 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | ||||

| 23 Ga | 143 | 204 | 260 | 352 | 352 | 352 | 352 | 352 | 352 | 352 | ||||

| 22 Ga | 143 | 204 | 260 | 352 | 487 | 487 | 487 | 487 | 487 | 487 | ||||

| 21 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 532 | 532 | 532 | 532 | ||||

| 20 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 575 | 575 | 575 | ||||

| 19 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 669 | 669 | ||||

| 18 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 759 | 759 | ||||

|

NR,k [kN] | 28 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 341 | 341 | 341 | ||

| 26 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 375 | 375 | 375 | ||||

| 25 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 449 | 449 | ||||

| 23 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 568 | ||||

| 22 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 21 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 20 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 19 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 18 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | Steel Quality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | Steel Quality S235 – according to EN 10025-2 en S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

Washer diameter

5/8 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | |||||

|

VR,k [kN] | 28 Ga | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | ||

| 26 Ga | 143 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | ||||

| 25 Ga | 143 | 204 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | ||||

| 23 Ga | 143 | 204 | 260 | 352 | 352 | 352 | 352 | 352 | 352 | 352 | ||||

| 22 Ga | 143 | 204 | 260 | 352 | 487 | 487 | 487 | 487 | 487 | 487 | ||||

| 21 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 532 | 532 | 532 | 532 | ||||

| 20 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 575 | 575 | 575 | ||||

| 19 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 669 | 669 | ||||

| 18 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 759 | 759 | ||||

|

NR,k [kN] | 28 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 382 | 382 | 382 | ||

| 26 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 395 | 395 | ||||

| 25 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 485 | ||||

| 23 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 627 | ||||

| 22 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 21 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 20 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 19 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 18 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | Steel Quality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | Steel Quality S235 – according to EN 10025-2 en S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

Washer diameter

3/4 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 28 Ga | 26 Ga | 25 Ga | 23 Ga | 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | |||||

|

VR,k [kN] | 28 Ga | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | 143 | ||

| 26 Ga | 143 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | ||||

| 25 Ga | 143 | 204 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | 260 | ||||

| 23 Ga | 143 | 204 | 260 | 352 | 352 | 352 | 352 | 352 | 352 | 352 | ||||

| 22 Ga | 143 | 204 | 260 | 352 | 487 | 487 | 487 | 487 | 487 | 487 | ||||

| 21 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 532 | 532 | 532 | 532 | ||||

| 20 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 575 | 575 | 575 | ||||

| 19 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 669 | 669 | ||||

| 18 Ga | 143 | 204 | 260 | 352 | 487 | 532 | 575 | 669 | 759 | 759 | ||||

|

NR,k [kN] | 28 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 382 | 382 | 382 | ||

| 26 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 395 | 395 | ||||

| 25 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 485 | ||||

| 23 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 627 | ||||

| 22 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 21 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 20 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 19 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

| 18 Ga | 80 | 103 | 123 | 157 | 209 | 263 | 314 | 395 | 472 | 629 | ||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | Steel Quality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | Steel Quality S235 – according to EN 10025-2 en S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 17 Ga | |

"